Gate valves DNOVA GVKR1331E-2W-Fb-2P interflanged, with sliding spindle, body - cast iron GGG-40, seal - EPDM, with pneumatic actuator, WENZ and induction sensors LJ12A3-4-J/EZ 220V

Couldn't load pickup availability

Collapsible content

Description

Gate valve is designed to be installed on the pipeline as a shut-off device and to regulate the flow of working medium in water supply systems (except drinking water supply systems) and chemical industry.

Pneumatic valves are used for control in pneumatic systems with NAMUR docking surface for installation of valves through through holes in the body. Electromagnetic control, is carried out by means of voltage coils 12-AC, 12-DC, 24-AC, 24-DC, 110-AC, 220-AC. Depending on the model, the valves are single- or double-acting. Solenoid operated pneumatic valves have a wide range of models and include common switching types for three (3/2) and five (5/2 and 5/3) line pneumatic valves. They are intended for use with gate valves with pneumatic cylinder. Application is also possible on other pneumatically actuated valves.

Technical characteristics of gate valves DNOVA GVKR1331E-2W-Fb-2P interflanged, with sliding spindle, body - cast iron GGG-40, seal - EPDM

Here’s the translation:

| Name | Value |

|---|---|

| Nominal pressure PN, bar | 10 |

| Type of connection | Flanged |

| Medium | Water |

| Type of control | Pneumatic actuator |

| Application | Water supply, heating, industry |

| Valve type | Gate valve |

| Working medium temperature, °C | From -30 to +110 |

| Country of manufacture | China |

Dimensions and dimensions of gate valves DNOVA GVKR1331E-2W-Fb-2P interflanged, with sliding spindle, body - cast iron GGG-40, seal - EPDM

| Size | DN50 | DN65 | DN80 | DN100 | DN125 | DN150 | DN200 | DN250 | DN300 |

| DN, mm | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| L, mm | 48 | 48 | 51 | 51 | 57 | 57 | 70 | 70 | 76 |

| D, mm | 165 | 185 | 200 | 220 | 250 | 285 | 340 | 395 | 445 |

| D1, mm | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 350 | 400 |

| D2, mm | 99 | 118 | 132 | 156 | 184 | 211 | 266 | 319 | 370 |

| D0, mm | 100 | 100 | 100 | 100 | 100 | 125 | 125 | 160 | 160 |

| H1 | 445 | 520 | 558 | 675 | 780 | 850 | 980 | 1140 | 1360 |

| G, | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ |

| N - Th | 4 – M16 | 4 – M16 | 8 – M16 | 8 – M16 | 8 – M16 | 8 – M20 | 8 – M20 | 12 – M20 | 12 – M20 |

| T, mm | 12 | 12 | 12 | 12 | 12 | 14 | 16 | 16 | 16 |

| Ød, mm | 18 | 18 | 18 | 18 | 18 | 23 | 23 | 23 | 23 |

| ⬤, mm | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 4 | 4 |

| 〇, mm | 2 | 2 | 6 | 6 | 6 | 6 | 6 | 8 | 8 |

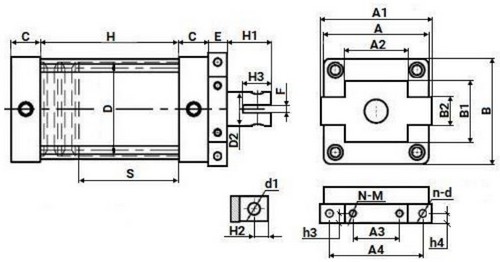

Sketch of dimensions and dimensions of gate valves DNOVA GVKR1331E-2W-Fb-2P interflanged, with sliding spindle, body - cast iron GGG-40, seal - EPDM

Table of parts and materials of gate valves DNOVA GVKR1331E-2W-Fb-2P interflanged, with sliding spindle, body - cast iron GGG-40, seal - EPDM

| No. | Details | Material |

|---|---|---|

| 1 | Body | Cast iron GGG40 |

| 2 | Sealing ring | EPDM |

| 3 | Gate | Stainless steel SS304 |

| 4 | Guide seal | PTFE |

| 5 | Packing | PTFE |

| 6 | Packing for gland | Steel WCB |

| 7 | Pin | Steel 45 |

| 8 | Cartridge | Steel WCB |

| 9 | Stem | Steel 2Cr13 |

| 10 | Stand | Steel Q235 |

| 11 | Switch | - |

| 12 | Pneumatic cylinder | - |

| 13 | Solenoid valve | - |

| 14 | Filter | - |

Sketch of parts and materials of slide gate valves DNOVA GVKR1331E-2W-Fb-2P interflanged, with sliding spindle, body - cast iron GGG-40, seal - EPDM

Technical parameters of SC pneumatic cylinders

| Name | Value |

|---|---|

| Model | SC |

| Construction | Double acting |

| Working environment | Compressed air |

| Contamination class | 6 according |

| Damping | Adjustable |

| Operating pressure range (bar) | 1-9 |

| Operating temperature range (°C) | from -5 to +70 |

Dimensions and dimensions of SC pneumatic cylinders

Here’s the translation for your table:

| Model | SC 100x70 | SC 100x85 | SC 100x100 | SC 100x120 | SC 100x145 | SC 125x170 | SC 125x220 | SC 160x270 | SC 200x320 |

|---|---|---|---|---|---|---|---|---|---|

| A, mm | 112 | 112 | 112 | 112 | 112 | 140 | 140 | 180 | 220 |

| A1, mm | 125 | 125 | 125 | 125 | 125 | 155 | 155 | 192 | 260 |

| A2, mm | 70 | 70 | 70 | 70 | 70 | 85 | 85 | 110 | 140 |

| A3, mm | 50 | 50 | 50 | 50 | 50 | 60 | 60 | 80 | 100 |

| A4, mm | 104 | 104 | 104 | 104 | 104 | 130 | 130 | 160 | 226 |

| h3, mm | 10 | 10 | 10 | 10 | 10 | 15 | 15 | 16 | 20 |

| h4, mm | 10 | 10 | 10 | 10 | 10 | 15 | 15 | 16 | 20 |

| N-M, mm | 4-M8 | 4-M8 | 4-M8 | 4-M8 | 4-M8 | 4-M10 | 4-M10 | 4-M12 | 4-M14 |

| n-d, mm | 2-Ø8.2 | 2-Ø8.2 | 2-Ø8.2 | 2-Ø8.2 | 2-Ø8.2 | 2-Ø10.2 | 2-Ø10.2 | 2-Ø12.2 | 2-Ø14.2 |

| B, mm | 112 | 112 | 112 | 112 | 112 | 140 | 140 | 180 | 220 |

| B1, mm | 75±0.5 | 75±0.5 | 75±0.5 | 75±0.5 | 75±0.5 | 95±0.5 | 95±0.5 | 105±0.5 | 105±0.5 |

| B2, mm | 32±0.5 | 32±0.5 | 32±0.5 | 36±0.5 | 36±0.5 | 42±0.5 | 42±0.5 | 48±0.5 | 48±0.5 |

| C, mm | 33 | 33 | 33 | 33 | 33 | 40 | 40 | 50 | 50 |

| D, mm | Ø100 | Ø100 | Ø100 | Ø100 | Ø100 | Ø125 | Ø125 | Ø160 | Ø200 |

| E, mm | 21 | 21 | 21 | 21 | 21 | 30 | 30 | 32 | 40 |

| F, mm | 6.2±0.1 | 6.2±0.1 | 6.2±0.1 | 6.2±0.1 | 6.2±0.1 | 8.2±0.1 | 8.2±0.1 | - | - |

| S, mm | 70±1 | 85±1 | 100±1 | 120±1 | 145±1 | 170±1 | 170±1 | 270±1 | 320±1 |

| H, mm | 96 | 111 | 126 | 146 | 171 | 205 | 255 | 320 | 360 |

| H1, mm | 35±1 | 34±1 | 34±1 | 28±1 | 28±1 | 33±1 | 33±1 | 30±1 | 30±1 |

| H2, mm | 12±0.5 | 12±0.5 | 12±0.5 | 12±0.5 | 12±0.5 | 14±0.5 | 14±0.5 | 23±0.5 | 23±0.5 |

| H3, mm | 24.5±1 | 24.5±1 | 24.5±1 | 24.5±1 | 24.5±1 | 28.5±1 | 28.5±1 | - | - |

| d1, mm | 10.2 | 10.2 | 10.2 | 10.2 | 10.2 | 12.2 | 12.2 | - | - |

| M, mm | - | - | - | - | - | - | - | M27x3 | M27x3 |

Sketch of dimensions and dimensions of SC pneumatic cylinders

Technical parameters of induction sensors LJ12A3-4

| Name | Value |

|---|---|

| Construction | Cylindrical |

| Sensor Type | Inductive |

| Current, mA | 400 |

| Switching Distance, mm | 4 |

| Switching Indication | Present |

| Protection Degree, IP | 67 |

Specifications

Delivery

The cost and delivery time for your order depend on several factors, including the specific product you are ordering, the quantity, and the country of destination. Each product may have different manufacturing lead times and shipping requirements, which can affect the overall delivery schedule.

To get the most accurate and up-to-date information on delivery costs and timelines, we recommend contacting our sales managers. They will be happy to provide you with a detailed quote and estimated delivery time based on your specific requirements.

Please feel free to reach out to us for any questions or further assistance regarding your order.

Didn't Find What You're Looking For?

Get a Personalized Quote from Our Team

Provide us with your specific requirements, technical specifications, and parameters. Our team of experts will carefully evaluate your needs and select the most suitable equipment for you, ensuring the best possible timeframe and competitive pricing.