Water Butterfly Valve DNOVA WBV1331E-2W-F-H, flanged, body - cast iron GGG40, disc - stainless steel 304, seal - EPDM, with pneumatic actuator PA-DA-105-1, with pneumatic distributor 4V320-10 220V, LSU APL-410N Ex, ATU AFC2000

Couldn't load pickup availability

Collapsible content

Description

DNOVA WBV1331E-2W-F-H butterfly valves are designed for use as shut-off or regulating valves for flow control in heat supply systems, water supply systems, in technological processes of food, chemical, oil and gas, pulp and paper and other industries.

Pneumatic valve DNOVA 4V320-10 220V is used to change the direction, start, stop the compressed air flow in the pneumatic system depending on the external control action.

The DNOVA APL-410N EX limit switch unit is an electrical device designed to open and close the working circuit and to visualise the positions of the shut-off body of pipeline valves. In a sealed box, as a rule, there are two mechanical switches designed for voltage up to 250 V, which monitor the position of the actuator stem and signalise extreme positions. They are mounted on top of the actuator surface. In the upper part of the limit switch unit there is a two-coloured visual indicator hemisphere. If the connected pipe fitting is closed, only the red part of the hemisphere labelled CLOSED is visible; if it is open, only the yellow part labelled OPEN is visible. This visual indicator is clearly visible from a distance, which simplifies the inspection of the equipment, and the colour difference between the open and closed position reduces the probability of misinterpretation of information. The use of the AFC2000 makes it possible to transmit information on the position of the valve (open/closed) to automated control systems, which increases the reliability of the system as a whole and simplifies diagnostics in case of malfunction detection.

The AFC2000 air treatment unit is designed to clean compressed air from moisture droplets and solid particles, remove condensate, automatically maintain pressure at a preset level, supply lubricant from the tank to the compressed air flow to the pneumatic system elements with a large capacity range from 500 litres/minute to 10,000 litres/minute. The lubricator (oil atomiser) adds oil with a viscosity of 32 mm²/s (=cSt) at 40°C to the pneumatic system for further lubrication of control components - pneumatic cylinders and pneumatic valves.

Technical parameters Rotary disc gate valves DNOVA WBV1331E-2W-F-H, flanged, body - cast iron GGG40, disk - stainless steel 304, seal - EPDM

| Name | Value |

|---|---|

| Nominal pressure PN, bar | 16 |

| Operating temperature, °C | from -25 to 130 |

| Application | water supply, industry, heating systems |

| Pipe connection | flanged |

| Valve type | rotary disc |

| Control type | pneumatic drive |

| Country of manufacture | China |

Dimensions and dimensions of Butterfly valves DNOVA WBV1331E-2W-F-H, flanged, body - cast iron GGG40, disk - stainless steel 304, seal - EPDM

| DN | L | D | F | L1 | G | X | Y |

| 50 | 108 | 125 | 153 | 495 | 147 | 88 | 162 |

| 65 | 112 | 145 | 153 | 495 | 147 | 88 | 162 |

| 80 | 114 | 160 | 153 | 495 | 147 | 88 | 162 |

| 100 | 127 | 180 | 153 | 495 | 147 | 88 | 162 |

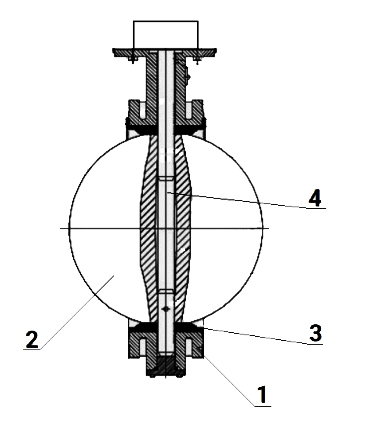

Sketch of rotary disc gate valves DNOVA WBV1331E-2W-F-H, flanged, body - cast iron GGG40, disk - stainless steel 304, seal - EPDM

Table of parts and materials for butterfly disc gate valves DNOVA WBV1331E-2W-F-H, flanged, body - cast iron GGG40, disk - stainless steel 304, seal - EPDM

| No. | Part Name | Material |

|---|---|---|

| 1 | Body | cast iron GGG40 |

| 2 | Disk | stainless steel 304 |

| 3 | Saddle sealing | EPDM |

| 4 | Stem | stainless steel SS 420 |

Technical parameters of pneumatic actuator PA-DA-105-1:

| Type of pneumatic actuator | double-acting |

| Control pressure, bar | 2 ÷ 8 |

| Operating temperature, °C | -20 to +80 |

| Visual position indicator | open / closed |

| Manual control | handwheel |

| Swivel angle, ° | 90 ± 5 |

| Top connection standard | NAMUR |

| Air connection standard | NAMUR |

| Air supply connection thread | G 1/4ʺ |

| ISO flange type | F07/F10 |

| Stem square, mm | 22x22 |

| Weight, kg | 9 |

| Average life, cycles closed/open | 300 000 |

Pneumatic actuator PA-DA-105-1

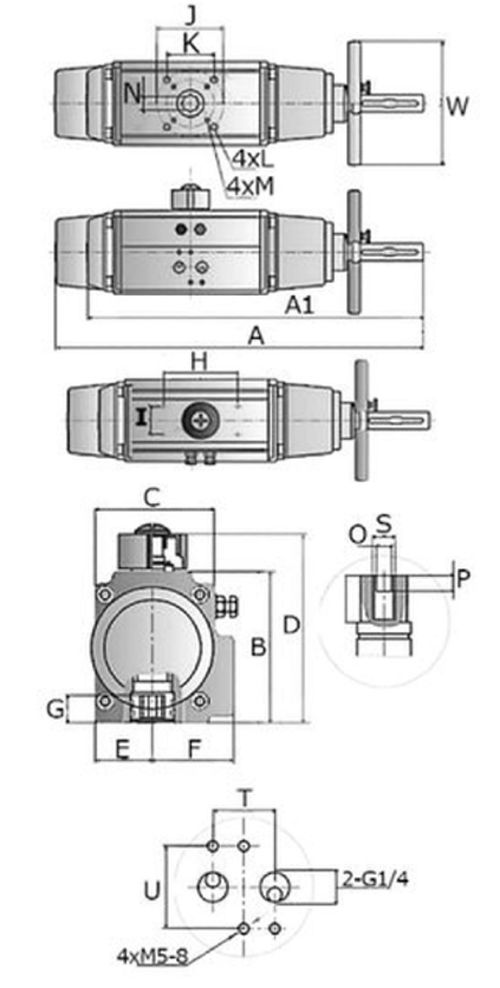

Dimensions and dimensions of the pneumatic actuator PA-DA-105-1:

| A, mm | 495 |

| A1, mm | 461.5 |

| B, mm | 133 |

| C, mm | 109.5 |

| D, mm | 153 |

| E, mm | 57.5 |

| F, mm | 64 |

| G, mm | 26 |

| H, mm | 80 |

| I, mm | 30 |

| N, mm | 22 |

| W, mm | 200 |

| J, mm | 102 |

| K, mm | 70 |

| L, mm | M10x16 |

| M, mm | M8x13 |

| O, mm | 4 |

| P, mm | 4 |

| S, mm | M6 |

| T, mm | 24 |

| U, mm | 32 |

Sketch of dimensions and dimensions of pneumatic actuator PA-DA-105-1

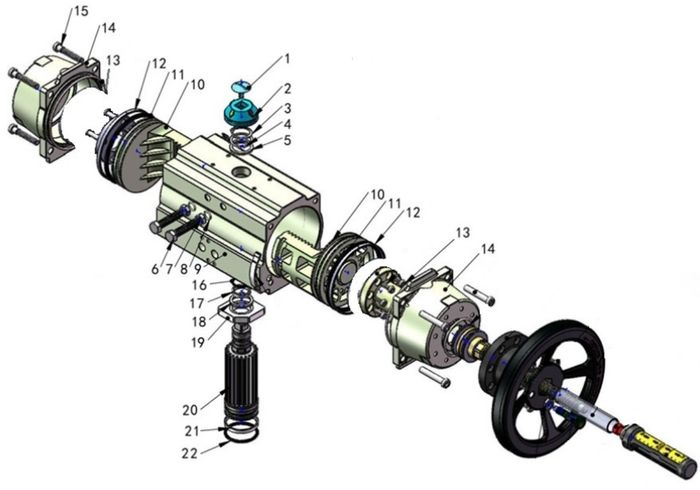

PA-DA-105-1 air actuator parts and materials table:

| № | Part name | Material |

| 1 | Indicator screw | ABS (plastic) |

| 2 | Position indicator | ABS (plastic) |

| 3 | Spring clip | Stainless steel 304 |

| 4 | Washer | Stainless steel 304 |

| 5 | External washer | Engineering plastic |

| 6 | Adjustment screw | Stainless steel 304 |

| 7 | Nut | Stainless steel 304 |

| 8 | Washer | Stainless steel 304 |

| 9 | Body | Extruded aluminum alloy |

| 10 | Piston | Die cast aluminum alloy |

| 11 | Piston O-ring | NBR |

| 12 | Bearing group | Engineering plastic |

| 13 | End cap O-ring | NBR |

| 14 | End cap | Die cast aluminum alloy coated with polyester paint |

| 15 | Fixing screw | Stainless steel 304 |

| 16 | Internal washer | Engineering plastic |

| 17 | Sealing ring | NBR |

| 18 | Bearing | Engineering plastic |

| 19 | Retainer | Alloy steel |

| 20 | Gear | Alloy steel |

| 21 | Bearing | Engineering plastic |

| 22 | Sealing ring | NBR |

Parts and material sketch of the PA-DA-105-1 pneumatic actuator

Technical parameters of pneumatic valve DNOVA 4V320-10 220V

| Name | Value |

|---|---|

| Type of pneumatic distributor | Spool type |

| Model of pneumatic distributor | 4V320-10 220V |

| Operating pressure, bar | 1.5 ÷ 8 |

| Supply voltage, V | 220 V |

| Switching frequency, cycle/sec | 5 |

Technical parameters of limit switch unit DNOVA APL-410N EX

| Name | Value |

|---|---|

| Model of limit switch module | APL-410N EX |

| Service life, years | 10 |

Parts and materials table for DNOVA APL-410N EX limit switch unit

| № | Part Name | Material |

|---|---|---|

| 1 | Visual indicator | ABS plastic / polycarbonate |

| 2 | Visual indicator cover | Polycarbonate |

| 3 | Label | |

| 4 | Cover screws | Stainless steel |

| 5 | BKV housing cover | Die-cast aluminum |

| 6 | Shaft | Stainless steel |

| 7 | Limit switches | |

| 8 | Cam (eccentric) | Polycarbonate |

| 9 | BKV housing | Die-cast aluminum |

| 10 | Terminal block | |

| 11 | Grounding terminal | Stainless steel |

| 12 | Hole (thread) for cable entry | |

| 13 | Bracket | Stainless steel |

Main parameters of the DNOVA AFC2000 air treatment unit

| Parameter | Value |

|---|---|

| Working pressure, bar | 8 |

| Maximum pressure, bar | 10 |

| Adjustable pressure range, bar | 0.5 ÷ 9 |

| Burst pressure, bar | 15 |

| Air connection | 1/4" |

| Working temperature, °C | from -5 to +60 |

| Filtered particle size, μm | 40 |

| Oil viscosity | ISO VG 32 |

| Weight, kg | 0.395 |

| Set contents | Filter-water separator, pressure regulator, lubricator, bracket |

Sketch of BPV DNOVA AFC2000

Specifications

Delivery

The cost and delivery time for your order depend on several factors, including the specific product you are ordering, the quantity, and the country of destination. Each product may have different manufacturing lead times and shipping requirements, which can affect the overall delivery schedule.

To get the most accurate and up-to-date information on delivery costs and timelines, we recommend contacting our sales managers. They will be happy to provide you with a detailed quote and estimated delivery time based on your specific requirements.

Please feel free to reach out to us for any questions or further assistance regarding your order.

Didn't Find What You're Looking For?

Get a Personalized Quote from Our Team

Provide us with your specific requirements, technical specifications, and parameters. Our team of experts will carefully evaluate your needs and select the most suitable equipment for you, ensuring the best possible timeframe and competitive pricing.