Ball valves DNOVA BV3131P(3pc)-FP-F-ISO-H DN65-80 16 bar three-piece full bore flanged, body - stainless steel SS304, seal - PTFE, with pneumatic actuator DNOVA PA-DA and LSU APL-210N

Couldn't load pickup availability

Collapsible content

Description

Ball valves are used as shut-off valves in heat and water supply systems, in steam, fuel and pneumatic systems with compressed air and neutral gases. Installation of valves of this series is possible in systems transporting liquid and gaseous media (water, oil, oils, steam, air, alcohols, glycol, etc.), non-aggressive to the materials of the valve. The use of ball valves as regulating valves is not allowed.

Pneumatic rotary actuator is designed to automate the process of control of industrial valves, as well as to determine the position of the valve shut-off body.

Limit switch unit is designed for visual and electrical signaling of the end positions of the shut-off valve, valve or disc gate. It is mounted on top of the pneumatic actuator surface and connected to the actuator shaft in DIN standard. The sealed box usually contains two sensors that monitor the position of the actuator shaft and signalize in extreme positions. OMRON microswitches, inductive sensors or reed switches are used as sensors. Visual indication of the position can be observed on the housing of the unit there is a 3D visual indicator RED-CLOSED and GREEN-OPEN.

Technical parameters of ball valves DNOVA BV3131P(3pc)-FP-F-ISO-H DN65-80 16 bar three-piece full bore flanged, body - stainless steel SS304, seal - PTFE, with pneumatic actuator DNOVA PA-DA and LSU APL-210N:

|

Parameter |

Value |

|

Nominal pressure PN, bar |

25 |

|

Working medium temperature, °C |

From -20 to 180 |

|

Type of valve device |

Two-way |

|

Application |

Water supply, Heat supply, Pneumatic systems |

|

Working medium |

Water, steam, oil products, liquid media, neutral media, gaseous media |

|

Connection to pipeline |

Flanged |

|

Type of passage section |

Full bore |

|

Control type |

With pneumatic actuator |

|

Connection |

Flanged |

|

Control |

Double-acting pneumatic actuator |

|

Presence of limit switches |

Yes |

|

Presence of pneumatic distributor |

No |

|

Presence of electro-pneumatic positioner |

No |

|

Warranty, years |

1 |

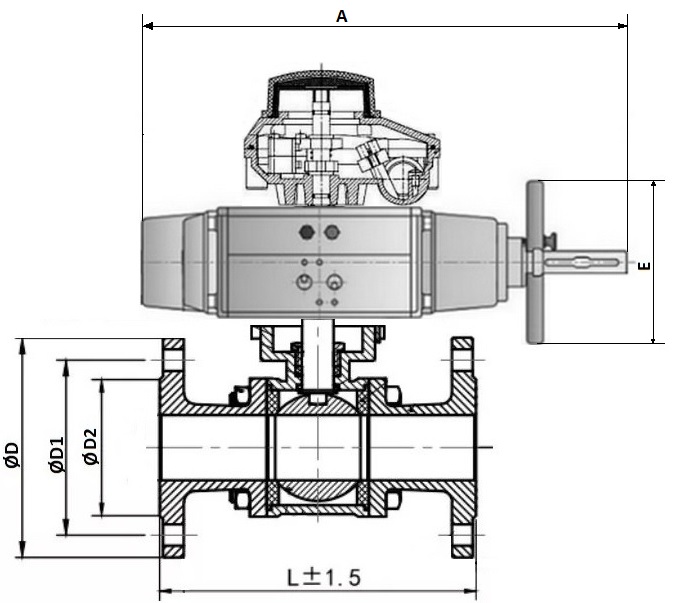

Dimensions and sizes of ball valves DNOVA BV3131P(3pc)-FP-F-ISO-H DN65-80 16 bar three-piece full bore flanged, body - stainless steel SS304, seal - PTFE, with pneumatic actuator DNOVA PA-DA and LSU APL-210N:

| DN | ØD, mm | ØD1, mm | ØD2, mm | L, mm | A, mm | Е, mm |

| 65 | 185 | 145 | 122 | 290 | 495 | 200 |

| 80 | 200 | 160 | 140 | 310 | 495 | 200 |

| 100 22х22, F10 | 220 | 180 | 158 | 350 | 495 | 200 |

Table of parts and materials of ball valves lephant BV3131P(3pc)-FP-F-ISO-H DN65-80 16 bar three-piece full bore flanged, body - stainless steel SS304, seal - PTFE, with pneumatic actuator DNOVA PA-DA and LSU APL-210N:

|

№ |

Part name |

Material |

Quantity |

|

1 |

Body |

Steel SS304 / SS316 |

1 |

|

2 |

Ball |

Steel S304 / S316 |

1 |

|

3 |

Bolt |

Steel S201 / S304 |

4~6 |

|

4 |

Nut |

Steel S201 / S304 |

6~12 |

|

5 |

Seal |

PTFE |

1 |

|

6 |

Stem |

Steel SS304 / SS316 |

1 |

|

7 |

Gland |

Steel S201 / S304 |

1 |

|

8 |

Cover |

Steel WCB/CF8/CF8M |

2 |

|

9 |

Seat rings |

PTFE |

2 |

|

10 |

Thrust washer |

PTFE |

1 |

Technical parameters of pneumatic actuators DNOVA PA-DA

| Name | Value |

| Construction | Double-acting |

| Control pressure, bar | 2 ÷ 8 |

| Availability of manual doubler | No |

Dimensions and sizes of pneumatic actuators DNOVA PA-DA

| Model of pneumatic actuator | PA-DA-105-1 |

| A, mm | 495 |

| A1, mm | 461.5 |

| B, mm | 133 |

| C, mm | 109.5 |

| D, mm | 153 |

| E1, mm | 57.5 |

| F, mm | 64 |

| G, mm | 26 |

| H, mm | 80 |

| I, mm | 30 |

| N, mm | 22 |

| E, mm | 200 |

| J, mm | 102 |

| K mm | 70 |

| L, mm | M10x16 |

| M, mm | M8x13 |

| O, mm | 4 |

| P, mm | 4 |

| S, mm | M6 |

| T, mm | 24 |

| U, mm | 32 |

Table of parts and materials for pneumatic actuators DNOVA PA-DA

|

№ |

Part name |

Material |

|

1 |

Indicator screw |

ABS (plastic) |

|

2 |

Position indicator |

ABS (plastic) |

|

3 |

Spring clamp |

Stainless steel 304 |

|

4 |

Washer |

Stainless steel 304 |

|

5 |

Outer washer |

Engineering plastic |

|

6 |

Adjustment screw |

Stainless steel 304 |

|

7 |

Nut |

Stainless steel 304 |

|

8 |

Washer |

Stainless steel 304 |

|

9 |

Body |

Extruded aluminum alloy |

|

10 |

Piston |

Pressure-cast aluminum alloy |

|

11 |

Piston sealing ring |

NBR |

|

12 |

Bearing group |

Engineering plastic |

|

13 |

End cover sealing ring |

NBR |

|

14 |

End cover |

Cast aluminum alloy, coated with polyester paint |

|

15 |

Fastening screw |

Stainless steel 304 |

|

16 |

Inner washer |

Engineering plastic |

|

17 |

Sealing ring |

NBR |

|

18 |

Bearing |

Engineering plastic |

|

19 |

Retainer |

Alloy steel |

|

20 |

Gear |

Alloy steel |

|

21 |

Bearing |

Engineering plastic |

|

22 |

Sealing ring |

NBR |

Technical parameters of limit switch units DNOVA APL-210N

| Name | Value |

| Model of limit switch unit | APL-210N |

| egree of protection of the housing, IP | 65 |

| Service life, years | 10 |

Dimensions and sizes of limit switch units DNOVA APL-210N:

| Model | H, mm | L, mm | B, mm | D, mm | D1, mm | M |

| APL-210N | 77 | 112 | 88 | 10 | 5 | 20x1.5 |

Table of parts and materials of limit switch unit DNOVA APL-210N:

|

Part |

Material |

|

Body |

Cast aluminum |

|

Indicator cap |

Polyester plastic |

|

3D indicator |

ABS-plastic |

|

Cam |

Polyester plastic |

|

Spring |

Stainless steel |

|

Screws |

Stainless steel |

|

Sealing rings |

NBR |

|

Bushing |

Bronze |

|

Grounding terminal |

Stainless steel |

|

Shaft |

Stainless stee |

Specifications

Delivery

The cost and delivery time for your order depend on several factors, including the specific product you are ordering, the quantity, and the country of destination. Each product may have different manufacturing lead times and shipping requirements, which can affect the overall delivery schedule.

To get the most accurate and up-to-date information on delivery costs and timelines, we recommend contacting our sales managers. They will be happy to provide you with a detailed quote and estimated delivery time based on your specific requirements.

Please feel free to reach out to us for any questions or further assistance regarding your order.

Didn't Find What You're Looking For?

Get a Personalized Quote from Our Team

Provide us with your specific requirements, technical specifications, and parameters. Our team of experts will carefully evaluate your needs and select the most suitable equipment for you, ensuring the best possible timeframe and competitive pricing.