Water Butterfly Valve DNOVA WBV1616E-2W-Fb-H, body material - cast iron QT450, disk material - cast iron QT450, seal - EPDM, pneumatic actuator PA-DA double action, positioner YT-1000RSN without feedback, handwheel MON

Couldn't load pickup availability

Collapsible content

Description

Butterfly valves are designed for use as shut-off or regulating valves for controlling flows in heat supply systems, water supply systems, in technological processes of food, chemical, oil and gas, pulp and paper and other industries. The valves are opened and closed by turning the disk by 90°. Opening is performed by turning the handle counterclockwise, closing - clockwise.

PA-DA double-acting pneumatic rotary actuators are designed to automate the process of controlling industrial valves with maximum torque up to 2128 Nm.

The manual doubleturn actuator with worm gear and HDM reduction gearbox allows manual setting of the required positioning of the shut-off valve by a quarter turn, acting as an alternative to pneumatic, electric or hydraulic quarter-turn actuators. Suitable for both indoor and outdoor installation. The modular design of the manual override is intended to provide the most efficient and effective solution to the full range of manual override applications.

The electropneumatic rotary positioner is used to control pneumatic rotary actuators using an electric controller or control system with an analog DC output signal with a range of 4 to 20 mA.

Technical parameters of Water Butterfly Valve DNOVA WBV1616E-2W-Fb-H, body material - cast iron QT450, disk material - cast iron QT450, seal - EPDM, pneumatic actuator PA-DA double action, positioner YT-1000RSN without feedback, handwheel MON:

| Name | Significance |

| Nominal pressure PN, bar | 16 |

| Working medium temperature, °C | from -20 to +150 |

| Application | water supply, heat supply |

| Connection to pipeline | Interflange (threaded lugs) |

| Gate type | swivel disk |

| Control type | pneumatic actuator |

| Manufacturer's country | China |

Butterfly valves WBV1616E-2W-Fb-H, body material - cast iron QT450, disk material - cast iron QT450, seal - EPDM, pneumatic actuator PA-DA double action, positioner YT-1000RSN without feedback, handwheel MON

Dimensions and dimensions of butterfly valves DNOVA WBV1616E-2W-Fb-H, body material - cast iron QT450, disk material - cast iron QT450, seal - EPDM, pneumatic actuator PA-DA double action, positioner YT-1000RSN without feedback, handwheel MON:

| DN | A | B | C | D | N-M (threaded holes) | H | The square of the shaft |

ISO 5211 |

| mm | ||||||||

| 50 | 72,5 | 130,5 | 43 | 125 | 4-М16 | 220 | 9х9 | F05 |

| 65 | 77,5 | 146,5 | 46 | 145 | 4-М16 | 220 | 9х9 | F05 |

| 80 | 92 | 156 | 46 | 160 | 8-М16 | 220 | 9х9 | F05 |

| 100 | 109 | 168,5 | 52 | 180 | 8-М16 | 260 | 11х11 | F07 |

| 125 | 127 | 190,5 | 56 | 210 | 8-М16 | 260 | 14х14 | F07 |

| 150 | 141 | 213,5 | 56 | 240 | 8-М20 | 260 | 14х14 | F07 |

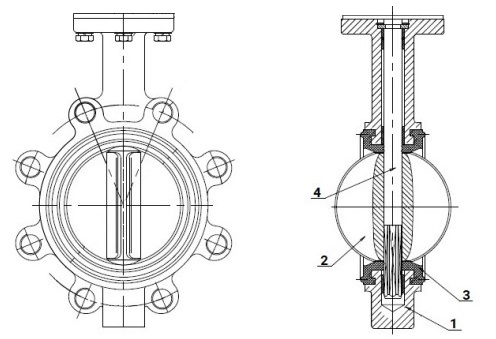

Sketch Butterfly valves WBV1616E-2W-Fb-H, body material - cast iron QT450, disk material - cast iron QT450, seal - EPDM, pneumatic actuator PA-DA double action, positioner YT-1000RSN without feedback, handwheel MON

Materials of butterfly valves DNOVA WBV1616E-2W-Fb-H, body material - cast iron QT450, disk material - cast iron QT450, seal - EPDM, pneumatic actuator PA-DA double action, positioner YT-1000RSN without feedback, handwheel MON:

| № | Details | Material |

| 1 | Body | cast iron QT450 |

| 2 | Disk | cast iron QT450 |

| 3 | Seat seal | EPDM |

| 4 | Rod | stainless steel SS 316 |

Sketch of parts and materials Butterfly valves WBV1616E-2W-Fb-H, body material - cast iron QT450, disk material - cast iron QT450, seal - EPDM, pneumatic actuator PA-DA double action, positioner YT-1000RSN without feedback, handwheel MON

Technical data of DA double-acting pneumatic actuators:

| Type of pneumatic actuator | DA - double-acting |

| Nominal pressure PN, bar | 12 |

| Working pressure, bar | 2...8 |

| Working medium | filtered compressed air |

| Maximum particle diameter of the working medium, µm2 | ≤30 |

| Ambient temperature, ⁰C | -20 to +80 |

| Swivel angle, ° | 0 - 90 |

| Swivel angle adjustment, % | ±5 |

| Position indicator | open/closed |

| Top connection standard | NAMUR |

| Air connection standard | NAMUR |

| Average life, cycles closed/open | 70 000 (for non-aggressive media and medium pressure and temperature values) |

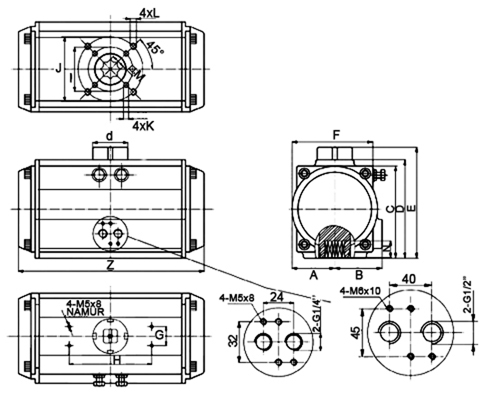

DA pneumatic actuators double-acting rotary actuators

Dimensions and mounting dimensions of DA double-acting pneumatic actuators:

| Model | A, mm | B, mm | C, mm | D, mm | E, mm | F, mm | G, mm | H, mm |

| DA-052 | 30 | 41,5 | 65,5 | 72 | 92 | 65 | 30 | 80 |

| DA-065 | 36 | 47 | 81 | 88 | 108 | 72 | 30 | 80 |

| DA-083 | 46 | 57 | 98,5 | 108,7 | 128,7 | 92 | 30 | 80 |

| DA-105 | 57,5 | 64 | 122,5 | 133 | 153 | 109,5 | 30 | 80 |

| DA-130 | 67,5 | 74,5 | 145,5 | 155 | 185 | 127,5 | 30 | 130 |

| DA-140 | 75 | 77 | 161 | 172 | 202 | 137,5 | 30 | 130 |

| DA-160 | 87 | 87 | 184 | 197 | 227 | 159 | 30 | 130 |

| DA-210 | 113 | 113 | 235,5 | 255 | 285 | 210 | 30 | 130 |

| DA-270 | 147 | 147 | 299 | 326 | 356 | 273 | 30 | 130 |

| DA-300 | 162 | 174 | 330 | 350 | 380 | 312 | 30 | 130 |

| DA-350 | 190 | 195 | 483 | 410 | 440 | 365 | 30 | 130 |

| Model | I, mm | J, mm | M, mm | N, mm | Z, mm | d, mm | K | L |

| DA-052 | 36 | 50 | 11x11 | 14 | 147 | 40 | M5x8 | M6x10 |

| DA-065 | 50 | 70 | 14x14 | 18 | 168 | 40 | M6x10 | M8x13 |

| DA-083 | 50 | 70 | 17x17 | 21 | 204 | 40 | M6x10 | M8x13 |

| DA-105 | 70 | 102 | 22x22 | 26 | 268 | 40 | M8x13 | M10x16 |

| DA-130 | 70 | 102 | 22x22 | 26 | 301 | 55 | M8x13 | M10x16 |

| DA-140 | 102 | 125 | 27x27 | 31 | 390 | 55 | M10x16 | M12x20 |

| DA-160 | 102 | 125 | 27x27 | 31 | 458 | 55 | M10x16 | M12x20 |

| DA-210 | - | 140 | 36x36 | 40 | 532 | 80 | - | M16x25 |

| DA-270 | - | 165 | 46x46 | 50 | 718 | 80 | - | M20x25 |

| DA-300 | - | 165 | 46x46 | 50 | 760 | 80 | - | M20x25 |

| DA-350 | 165 | 254 | 46x46 | 50 | 920 | 80 | M20x25 | 8xM16x25 |

Sketch of dimensions of DA double-acting pneumatic actuators

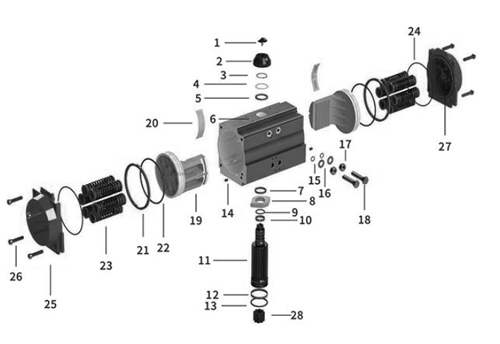

Materials of parts for DA double-acting pneumatic actuators:

| № | Part name | Material |

| 1 | Indicator screw | ABS plastic |

| 2 | Position indicator | ABS plastic |

| 3 | Spring clip | stainless steel 304 |

| 4 | Metal washer | stainless steel 304 |

| 5 | Pressure washer | engineering plastic |

| 6 | Housing | hard anodized extruded aluminum alloy |

| 7 | Pressure washer | engineering plastic |

| 8 | Limiter | alloy steel |

| 9 | Shaft sealing ring upper | NBR |

| 10 | Upper shaft sliding ring | engineering plastic |

| 11 | Shaft | nickel plated alloy steel |

| 12 | Shaft sliding ring lower | engineering plastic |

| 13 | Shaft O-ring lower | NBR |

| 14 | Plug | NBR |

| 15 | Seal ring of adjusting screws | NBR |

| 16 | Washer of adjusting screw | stainless steel 304 |

| 17 | Lock nut of adjusting screw | stainless steel 304 |

| 18 | Adjusting screw | stainless steel 304 |

| 19 | Piston | die-cast aluminum alloy |

| 20 | Piston guide plate | engineering plastic |

| 21 | Piston sliding ring | engineering plastic |

| 22 | Piston O-ring | NBR |

| 23 | Spring set | spring steel |

| 24 | Cover O-ring | NBR |

| 25 | End cap | cast aluminum with polyester coating |

| 26 | Cover screw | stainless steel 304 |

| 27 | Stop screw | stainless steel 304 |

| 28 | Adapter | carbon steel |

Material sketch of DA double-acting pneumatic actuators

Technical parameters of electropneumatic rotary positioners:

| Name | Value |

| Control input signal, mA | 4 ~ 20 |

| Internal resistance, Ohm | 250(±15) |

| Input pressure, bar | 1,4~7 |

| Lever travel angle | 0~90° |

| Compressed air connection thread | 1/4″ |

| Pressure gauge connection thread | 1/8″ |

| Cable gland | G1/2″ |

| Protection type | IP66 |

| Compressed air flow rate, l/min | 3 |

| Output air flow rate, l/min | 80 |

| Housing material | aluminum casting |

Electropneumatic rotary positioners

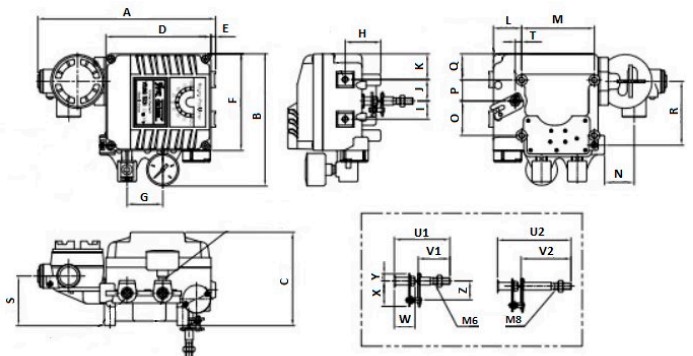

Dimensions and dimensions of electropneumatic rotary positioners:

| Positioner model | YT-1000RSN |

| A, mm | 224.3 |

| B, mm | 166.5 |

| C, mm | 117.5 |

| D, mm | 132.3 |

| E, mm | 6 |

| F, mm | 122 |

| G, mm | 45 |

| H, mm | 45 |

| I, mm | 23 |

| J, mm | 27 |

| K, mm | 32.5 |

| L, mm | 35.5 |

| M, mm | 91.8 |

| N, mm | 37.2 |

| O, mm | 43.5 |

| P, mm | 26.5 |

| Q, mm | 33 |

| R, mm | 80.25 |

| S, mm | 62.5 |

| T, mm | 8 |

| U1, mm | 70 |

| U2, mm | 93 |

| V1, mm | 40 |

| V2, mm | 63 |

| W, mm | 26 |

| X, mm | 32 |

| Y, mm | 9 |

| Z, mm | 24 |

Sketch of dimensions and dimensions of electropneumatic rotary positioners

Technical parameters of the handwheel MON:

| Name | Value |

| Climatic version | U,UHL,T,OM |

| Degree of protection, IP | 67 |

| Connection type | ISO 5211 |

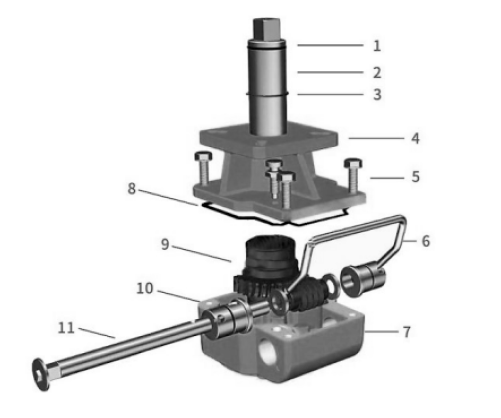

Manual doubler MON

Manual doubler MON

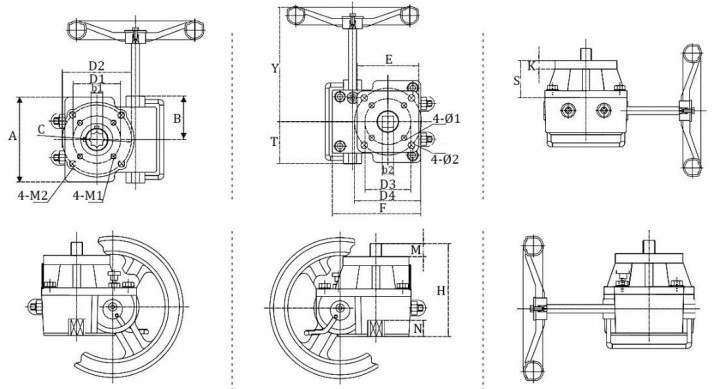

Dimensions and dimensions of the handwheel MON:

| Model | MON1-250-T26-ISO | MON2-450-T28-ISO | MON3-700-T38-ISO | MON4-1200-T54-ISO |

| b1, mm | 14 | 17 | 22 | 27 |

| N, mm | 22 | 22 | 28 | 32 |

| b2, mm | 14 | 17 | 22 | 27 |

| M, mm | 16 | 18 | 22 | 30 |

| D1, mm | Ø50 | Ø70 | Ø102 | Ø102 |

| 4-M1, mm | 4-M6 | 4-M8 | 4-M10 | 4-M10 |

| D2, mm | Ø70 | Ø102 | Ø125 | Ø125 |

| 4-M2, mm | 4-M8 | 4-M10 | 4-M12 | 4-M12 |

| E, mm | 70x70 | 95x95 | 114x114 | 129x129 |

| D3, mm | Ø50 | Ø70 | Ø102 | Ø125 |

| 4-Ø1, mm | 4-Ø6.5 | 4-Ø8.5 | 4-Ø10.5 | 4-Ø12.5 |

| D4, mm | Ø70 | Ø102 | Ø125 | Ø140 |

| 4-Ø2, mm | 4-Ø8.5 | 4-Ø10.5 | 4-Ø12.5 | 4-Ø16.5 |

| A, mm | 90 | 125 | 140 | 188.5 |

| B, mm | 55 | 64 | 71 | 93 |

| ØC, mm | Ø88 | Ø110 | Ø129 | Ø174 |

| F, mm | 115 | 135 | 166 | 202 |

| T, mm | 44 | 62.5 | 70 | 94 |

| Y, mm | 145 | 178 | 212 | 280 |

| H, mm | 120 | 133 | 180 | 195 |

| S, mm | 53 | 56.5 | 68.7 | 84 |

| K, mm | 10 | 13 | 12.5 | 15 |

| Ø hand wheel, mm | 180 | 200 | 280 | 320 |

Sketch of dimensions and dimensions of the MON handwheel MON

Sketch of dimensions and dimensions of the MON handwheel MON

MON handwheel materials:

| № | Name | Material |

| 1 | Stem for mounting the pneumatic actuator | Steel 45 |

| 2 | Sealing ring | EPDM |

| 3 | Fixing spring | Spring steel |

| 4 | Upper end cover | Aluminum alloy |

| 5 | Screw | Steel 304 |

| 6 | Locking bracket (main rod) | Steel 304 |

| 7 | Housing | Aluminum alloy |

| 8 | Sealing ring | EPDM |

| 9 | Gear unit | Cast iron BCh50 |

| 10 | Transition coupling | Cast iron BCh40 |

| 11 | Gear stem | Cast iron BCh40 |

Materials of the handwheel

Specifications

Delivery

The cost and delivery time for your order depend on several factors, including the specific product you are ordering, the quantity, and the country of destination. Each product may have different manufacturing lead times and shipping requirements, which can affect the overall delivery schedule.

To get the most accurate and up-to-date information on delivery costs and timelines, we recommend contacting our sales managers. They will be happy to provide you with a detailed quote and estimated delivery time based on your specific requirements.

Please feel free to reach out to us for any questions or further assistance regarding your order.

Didn't Find What You're Looking For?

Get a Personalized Quote from Our Team

Provide us with your specific requirements, technical specifications, and parameters. Our team of experts will carefully evaluate your needs and select the most suitable equipment for you, ensuring the best possible timeframe and competitive pricing.